The complexity of vehicles and their technical possibilities is increasing. In the past, development engineers could develop parts of a car in silos, largely independently of each other. Today, due to the large amounts of software, everything is connected to everything else, be it infotainment systems, air conditioning, engine control, or brakes. There are many dependencies within the car and with external backend systems. This complexity requires new procedural models in development.

With the increase in the amount of software and complex dependencies between different vehicle systems, the methods of product development in automotive engineering must also adapt. On top of this, when developing safety-critical driving functions, automobile manufacturers have to comply with a growing range of verification and approval requirements, such as those specified by standards such as ISO 26262 (functional safety) and ISO 21434 (cyber security). In the environmental field, too, more recent standards such as WLTP are leading to much greater complexity in verification and documentation.

This is why engineers today employ systems engineering methodology and modeling languages to develop complete digital systems that simulate and describe system functions and dependencies with other systems. Based on these digital systems, it is possible to check whether they function correctly at an early stage. This also requires the use of new applications that must be integrated with each other. But the classic PLM application, for example, does not go far enough. Application-centric development is changing to data-centric thinking. The key to this is the concept of the Semantic Web. Thanks to this data-centric approach, different engineers use the same data for their respective tasks and feed their changes back into the overall system.

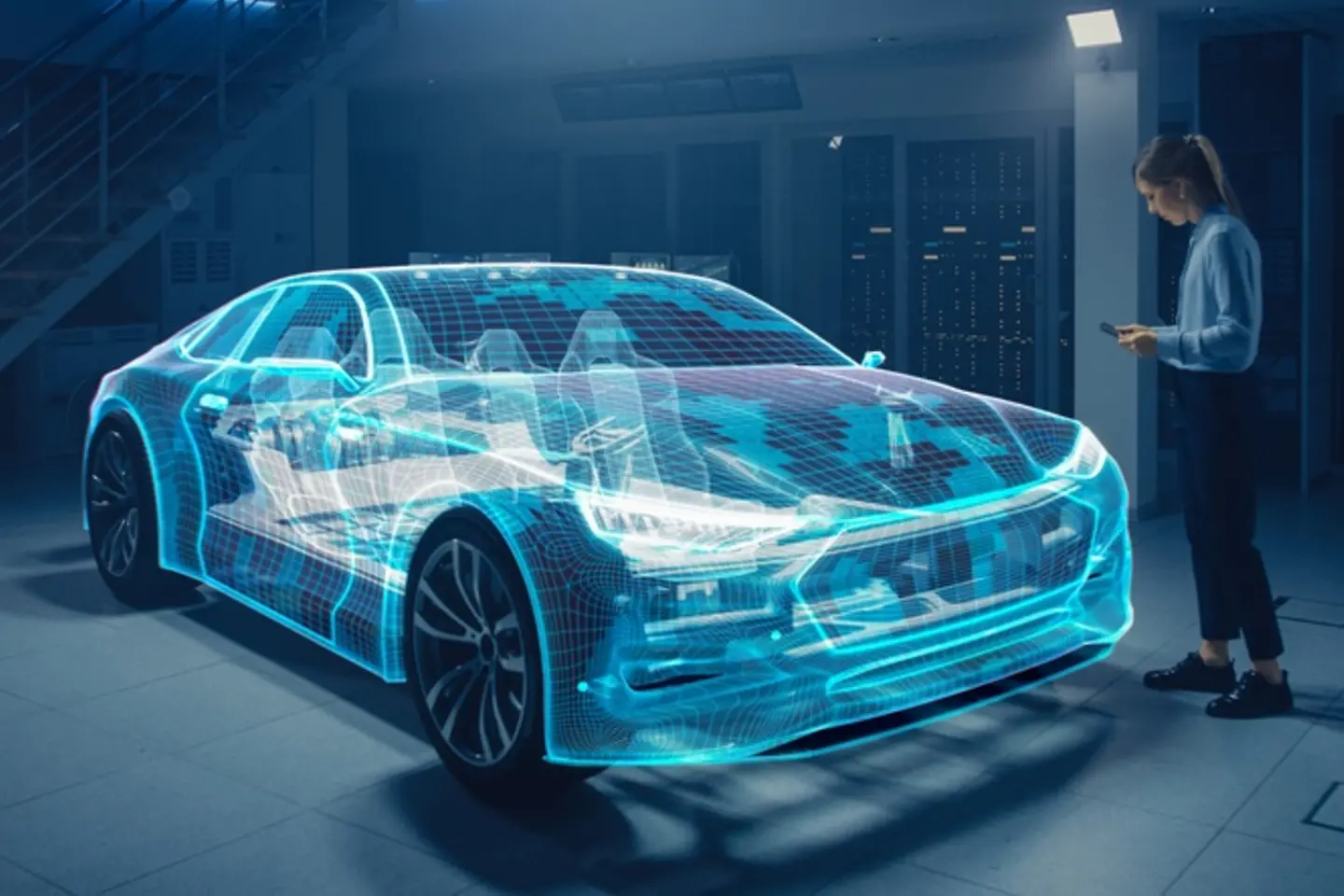

More and more car manufacturers are using software to create digital twins of their vehicles. Data from development, vehicle components, or later vehicle use flow into the virtual representation. Vehicle development in particular benefits from digital twins, as they allow the testing of developments of complex vehicle systems on digitally simulated components.

Until now, vehicle parts or control unit software have first been developed and then given a test drive. The test results are then incorporated into improvements. This process takes months, and the car manufacturers have to repeat these tests several times until the desired or required driving characteristics are achieved. Digital twins, on the other hand, simulate the properties of vehicle components in certain driving situations and can thus accelerate development enormously.

According to the International Society for Systems Engineering (INCOSE), MBSE is the formalized application of modeling a system to support system requirements, design, analysis, verification, and validation, starting in the conceptual design phase and continuing throughout the development and later life cycle phases. And for good reason: due to the complexity and the interdependencies of systems, even changing just one line of code can have an enormous impact on an entire system. This makes it difficult to model the further development of the system in a meaningful way.

In contrast to model-based development, for example with CAD, PLM, or FEM, the MBSE describes a system across disciplines. The system model essentially supports the cooperation and communication of all disciplines represented in the project; and does so from very early on in the project. The system model can be used by all disciplines for different purposes. In essence, it concerns system architecture for describing the mode of operation and behavior of a mechatronic system.