In today’s competitive landscape, manufacturers struggle to optimize efficiency, minimize environmental impact, and maintain profitability. Balancing these demands can feel like walking a tightrope, with traditional methods in the manufacturing process often falling short. The good news? The era of smart manufacturing has arrived. By harnessing the power of cutting-edge IT solutions, you can transform your operations and achieve the coveted triple bottom line: economic prosperity, environmental stewardship, and social responsibility. At T-Systems, we don’t just offer technology; we partner with you to build a future-proof manufacturing ecosystem that delivers tangible results.

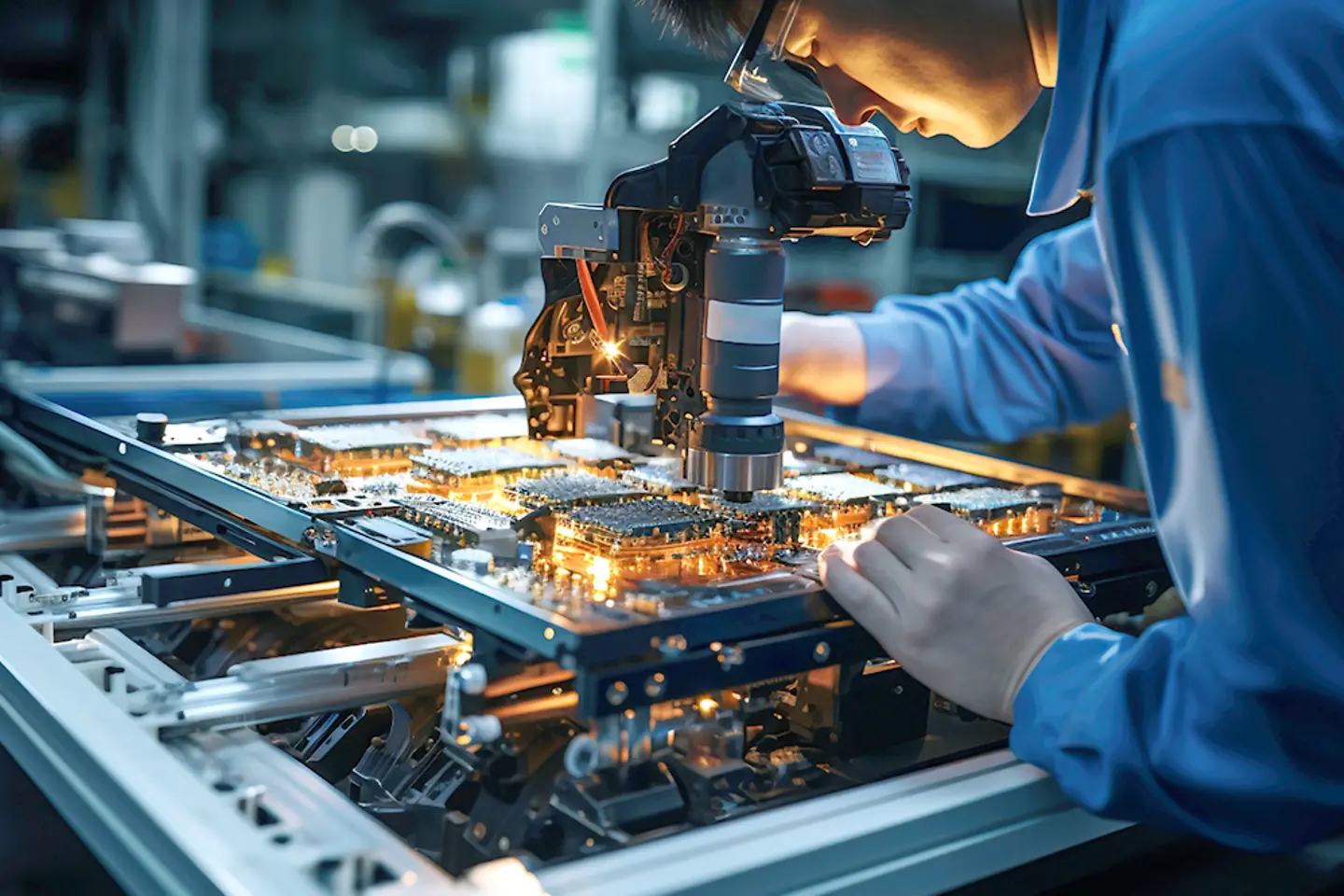

Imagine the impact of merging the physical production processes and operations in your factory with digital technology, smart computing, automation, and data intelligence. This is where smart factories come in – they offer the opportunity to create new forms of efficiency, flexibility, and service by connecting different processes, data streams, and stakeholders (such as product development, frontline workers, planners, supply chain, and more) in a streamlined fashion to enable bottom line growth.

Smart manufacturing enablers – such as Internet of Things (IoT), Industrial Internet of Things (IIoT), cloud computing, Artificial Intelligence (AI) and machine learning, edge computing, cyber security, data analytics, robotics, sensors, digital twin – are designed to reduce the need for reactive practices, making supply chain management increasingly resilient. This data-driven approach, fueled by predictive analytics and big data, provides factories with real-time insights to optimize and automate processes, manage inventory efficiently, forecast demand accurately, and bring products to market faster. Additionally, by integrating digital insights into workflows, workers gain valuable efficiencies, propelling overall productivity to new heights.

Data and connectivity create better insights, enabling a front-loaded and knowledge-driven process to boost profitability. The other benefits of this approach include energy efficient production, higher quality and lesser waste, reduced time-to-market, decelerated risks, minimized environmental impact, safer work environments, and an improved flexibility to thrive in a dynamic market. The transformation has begun, and it is time to join the smart manufacturing revolution.