Artificial intelligence is revolutionizing the ramp-up of the aerospace industry with intelligent technologies and autonomous systems. AI solutions are driving sustainable innovation, modernizing manufacturing processes, maintenance operations and flight experiences. But there are crucial questions ahead: Can we trust AI in aviation? And does Europe have the strategy and capabilities to stay ahead? Sovereignty and trustworthy AI will define the next frontier of smart aerospace.

Fierce competition is not really a new topic in the aerospace sector. Indeed, it seems to be in the DNA of aircraft manufacturing circling back to the first days of aviation. In 1783, France hosted the first great race to the skies, one of history’s most spectacular technological rivalries. The Montgolfier brothers believed hot air could lift a balloon, while physicist Jacques Charles and the Robert brothers used hydrogen gas. The Montgolfiers first impressed the public in June with an unmanned test, then made history in November with the first manned flight over Paris, lasting 25 minutes. Just then days later, Charles and the Roberts took off with the first manned hydrogen balloon, traveling even farther and higher. In only six months, two competing ideas had taken humanity into the skies.

Throughout the centuries, competition stayed a motive in aerospace, until today. Innovation is still crucial, but in the 21st century, it is accompanied by topics such as sustainability, production efficiency, supply chain disruptions, and geopolitics.

However, to stay ahead amidst the global competition, aerospace companies must ensure the digital sovereignty of their ICT systems. AI services need to evolve from general-purpose commodities into trusted specialist tools: robust, secure, scalable, transparent, and aligned with fair AI principles. Only then can they deliver explainable, repeatable, and certifiable outcomes, and gain the necessary accreditation from authorities such as the European Union Aviation Safety Agency (EASA), the Federal Aviation Administration (FAA), and the Civil Aviation Administration of China (CAAC).

AI is not rocket science anymore, it is already used for several cases within aerospace manufacturing and flight operations.

László Bertalan Gyányi, Global Account Director of Discrete and Process Manufacturing at T-Systems

NASA and SpaceX, for instance, are using AI widely. SpaceX uses AI for navigation and control, rocket technology, and satellites; its Crew Dragon spacecraft uses autonomous control systems that incorporate AI elements to perform maneuvers and dock with the International Space Station (ISS). Machine learning models are used in the Falcon 9 landing maneuver to enable precise landings on sea platforms. AI in the Starlink constellation is used to optimize satellite operations (routing, collision avoidance).

NASA uses AI for autonomous navigation of space probes, analysis of earth observation data, predictive maintenance for space stations and spacecraft, and within the DARPA project (Defense Advanced Research Projects Agency) for future Mars missions.

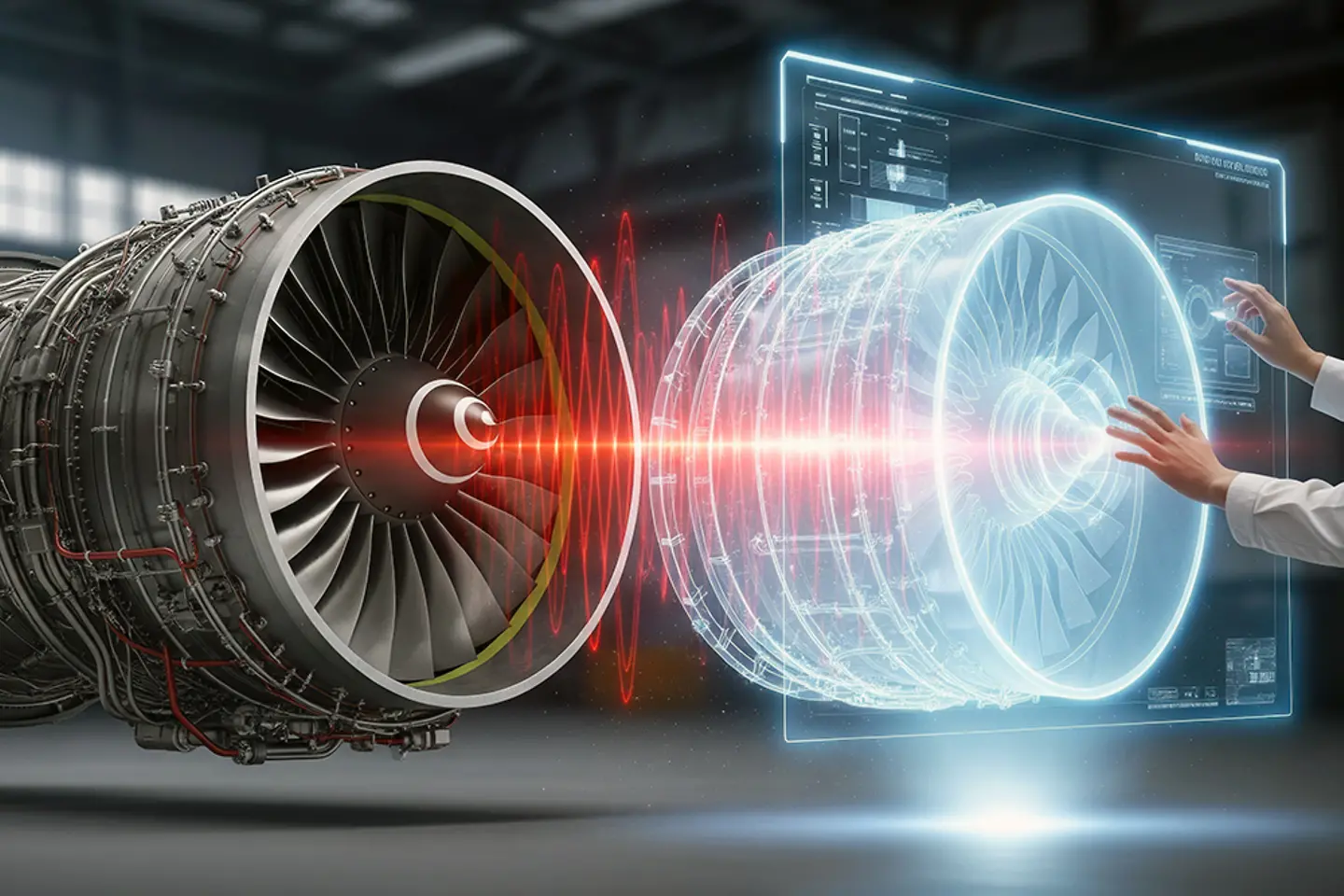

The examples of SpaceX and NASA shed some light on the usage of AI in aerospace. AI is used when huge amounts of data need to be analyzed, when complex problems with many variations need to be solved or, as a specific case of the latter, when objects need to fly “on their own”, autonomously. These use cases show the value of physical AI in aerospace. AI becomes a part of the products and on-board services. AI turns into a competitive factor: the age of the smart aerospace industry and software-defined aerospace arises.

AI scenarios can be classified based on their horizontal and vertical usage. For sure, well-known (Gen)AI scenarios for knowledge management can be utilized in aerospace, such as knowledge management tools, chat bots, in computer vision (CV), anomaly detection, or decision support. But AI can also bring very specific value addition to aerospace, as a part of autonomous systems and flight supporting services (for pilots), for instance.

Knowledge management and conversational assistance for maintenance teams are well-established across different industries. AI-based knowledge management tools can evaluate unstructured data from technical manuals, maintenance logs, and development documentation. They extract instructions and component data from PDFs, CAD documentation, or scanned documents and summarize relevant insights from decades of development projects or international regulations, thereby accelerating product development. Such AI services can also help create solutions for traceability or Certificates of Conformity.

Conversational assistance provides dialog systems for technical support or processes. Internal chatbots for maintenance teams can, for example, be asked: “What steps are necessary when replacing the Auxiliary Power Unit?” The AI, which has access to the technical documentation, ERP databases, knowledge databases, and training materials, serves as a help desk to answer the question. It can also cover maintenance planning or parts ordering. It unburdens support and technical teams and allows for faster response times to problems.

Besides the well-established industry-independent generative AI (GenAI) use cases, AI can be used in specific aerospace areas. However, aerospace can also be seen as a part of manufacturing. So, the manufacturing use cases as in automotive, for instance, apply optimization of components (such as, with generative design and simulation) in the design phase, optimization of product lines, and detection of defects through CV in quality control.

CV analyzes images and videos to recognize objects and conditions. In aircraft construction, CV automates quality inspection of components using cameras and finds issues such as paint defects, rivets, or surface cracks. It can monitor production halls to detect hazards, safety violations, or deviations in the process. It can use drones to inspect the aircraft fuselage (upon delivery or after landing). Thus, it reduces error rates and improves quality.

AI can play a key role in optimizing production lines and factory planning. However, it merely takes this optimization to the next level. The foundation for truly optimized production lies in a consistent data basis and real-time visualization, enabling the simulation of various scenarios. This is where industrial metaverses come into play, providing not only immersive planning environments, but also GPU resources to support AI development and operations. Industrial metaverse users report reduction in factory planning times by up to one third and operational cost savings of around 20 percent.

The NASA and SpaceX examples illustrate that AI can and should be a part of the product to allow autonomous and assisted flights (which are, by the way, easier than autonomous driving on the earth’s surface as there are no trees or pedestrians in the air or in space, at least most of the time). These autonomous capabilities can not only run on unmanned aircrafts but also support pilots as assistance systems. Another AI use case is the analysis of the sensor data collected during a flight. This can support predictive maintenance.

There is an abundance of AI use cases in aerospace and AI creates a competitive edge for any aerospace company. However, enterprises need to be able to fully utilize the potential of AI. We observe some basic challenges in leveraging AI in aerospace: many companies face skill gaps and don’t have access to necessary resources such as GPUs to train and run own models. Missing sovereign cloud capabilities make it hard to scale AI, and to protect intellectual property.

The final, and the most important point isn’t about technology at all: it’s about building trust in AI and bridging the gap between business and tech. The aerospace industry needs to start with trustworthy AI use cases that offer excellent business value. For that, it needs to have a strategy. And it needs to control the whole IT stack from infrastructure to platform, models, and applications. It needs to build its own AI factories.

The key components of the AI factory include sovereign clouds, sufficient GPU capacity, and AI skills. In aerospace, the need for sovereignty is undisputed driven by intellectual property, independence, and high responsibility. Traditionally, sovereignty was achieved through on-premises systems, but these cannot close the innovation gap or scale AI services. Only the cloud can. The logical conclusion: aerospace needs sovereign clouds without vendor lock-in to power its AI factory.

With a European partner such as T-Systems, sovereign cloud is not fiction. With the T Cloud, T-Systems offers a wide range of sovereign cloud solutions that are operated exclusively within Europe. Within 2026, these offers will be supplemented by the Industrial AI cloud providing NVIDIA GPU resources of the latest generation. With this aerospace will be able to train own models for best fit to aerospace purposes using the best, highly sensitive, data creating trustworthy AIs.

With an own AI factory of about 1,000 FTE and extensive consulting skills, T-Systems can help define the best AI approaches und use cases for the industry. Furthermore, it can supplement internal skills to breathe life into AI applications for aviation. Let’s create your roadmap to AI innovation to enter the age of the smart aerospace industry and create a competitive edge for you.