The first thing that comes to mind for most people is the consumer metaverse, which includes topics like avatars, virtual reality, gaming, and Meta (former Facebook). The consumer metaverse was a big hype a few years ago, and now that hype has slowed down. The industrial metaverse is a different story. So, what is the Industrial Metaverse?

The industrial metaverse is a highly advanced digital platform that offers a three-dimensional, immersive, and interactive representation of the physical world in industry. It is designed to integrate various technologies such as virtual reality (VR), augmented reality (AR), machine learning, IoT and 5G to enable real-time monitoring, analysis, and control of industrial processes. The platform has many tools and features that can simulate complex scenarios and help industries optimize operations, reduce downtime, and enhance productivity.

However, the concept of the Industrial Metaverse is still evolving, and its full potential has yet to be explored. As technology progresses, it's expected to revolutionize how we perceive, operate, and manage industrial processes.

T-Systems has been helping our customers by implementing an industrial metaverse for various industries and business areas. We have seen our customers gaining significant benefits by utilizing the industrial metaverse. So, what have we done with our customers?

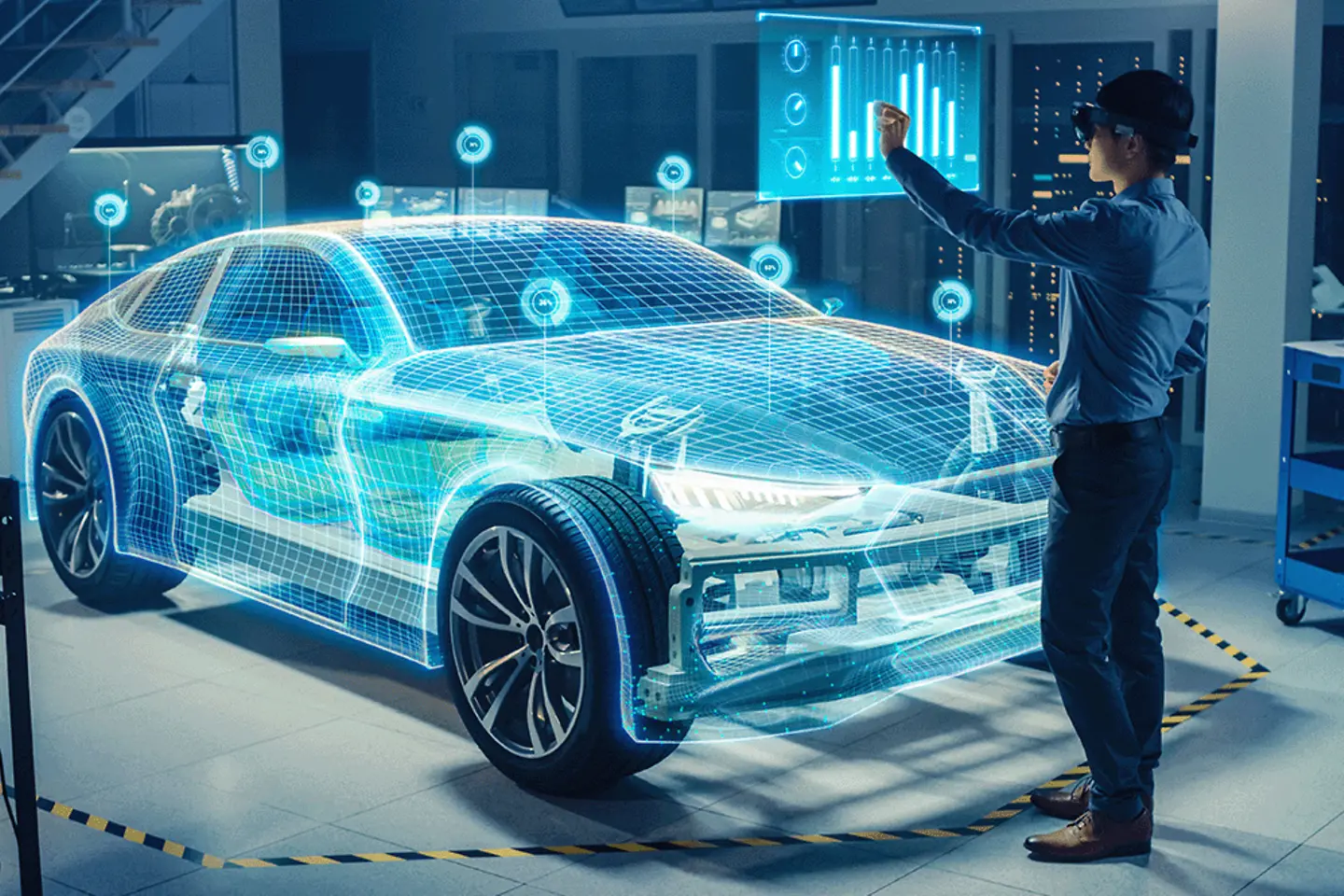

A leading automotive company based in Southern Germany used the Industrial Metaverse to facilitate location-independent collaboration between its engineering units, even with those outside the company. This led to a more interactive and inclusive design process as engineers from different units could collaborate virtually to design new components in interactive sessions.

Once a component is completed, Industrial Metaverse takes it a step further. It simulates the component’s use in the vehicle by 'installing' the new component virtually. This simulation results in a digital twin, a virtual replica of the car, which serves as a blueprint for product construction.

Furthermore, the Industrial Metaverse provided the customer’s engineers with a comprehensive overview of product component metadata such as price, manufacturer, delivery time, and carbon footprint. This insight enabled them to understand better the holistic impact of any changes to a component on the vehicle.

A manufacturing company aimed to increase equipment efficiency and reduce time to market by creating an industrial metaverse. The solution enabled the customer's new factories to become digital mega plants, driving the digitalization of their production environment forward.

In addition, observation and engagement with the frontline workers on-site can be facilitated virtually, showcasing shop floor activity for management in real-time. Managers can access the virtual production site via remote web access and monitor physical factory operations worldwide.

The industrial metaverse enables more efficient virtual layout planning, shop floor audits, and footprint simulations

The Industrial Metaverse is not just revolutionizing the automotive and manufacturing industries but also has the potential to transform other industries such as healthcare, banking, logistics and others by digitizing processes, promoting collaboration, efficiency, and insights.

Technology is evolving rapidly and is expected to incorporate emerging technologies such as AI. AI can help analyze the enormous amount of data generated, provide predictive insights, and automate various processes to take the virtual world of industrial metaverse to the next level.

The Industrial Metaverse offers exciting possibilities for the future, but also brings new challenges around data privacy and security. Continued innovation will change the industry as we know it. We have only seen the tip of the iceberg.