Rapidly growing manufacturers face challenges in a data-driven industry where rigid systems hinder swift, informed decision-making. ASTA, a global producer of winding wires and electric cables, sought a flexible solution to empower innovation and data-driven insights. With factories in Brazil and decades of expertise, ASTA partnered with T-Systems for a tailored business intelligence (BI) solution to enhance data analysis capabilities.

The new system has completely transformed how we handle data. We’re no longer stuck in a rigid framework – we can adapt quickly, experiment with different analyses, and pull insights that help us make better, faster decisions.

Luis Tadeau Marson, ASTA Brazil

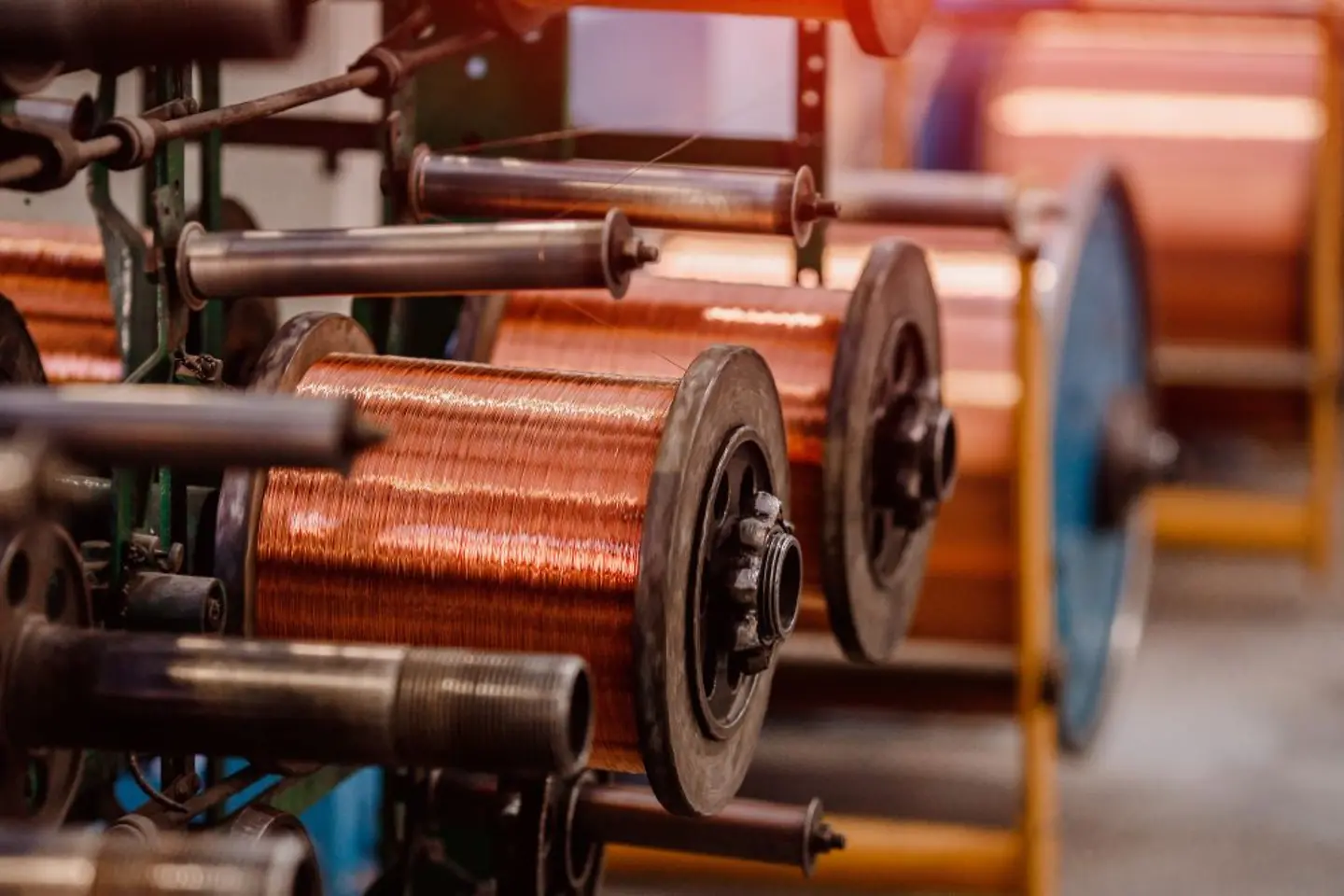

ASTA (also known as PPE Fios Esmaltados) is a producer of winding wires, offering a line of electric wires and cables for the generation of electromagnetic fields. The company also provides solutions for auto parts, hermetic motors, home appliances, electronics, generators, lighting, meters, motors, traction motors, and transformers.