In a significant move to bolster the European manufacturing sector, T-Systems and Drees & Sommer have announced a collaboration to integrate the NVIDIA Omniverse™ platform into factory planning and operations. This initiative aims to enhance efficiency, reduce costs, and promote sustainability across various industrial sectors.

European manufacturers are currently navigating a complex landscape marked by escalating energy prices, stringent regulatory requirements, and a shortage of skilled labor. These challenges necessitate innovative solutions to maintain global competitiveness. The integration of advanced digital technologies, such as NVIDIA Omniverse, offers a pathway to address these issues effectively.

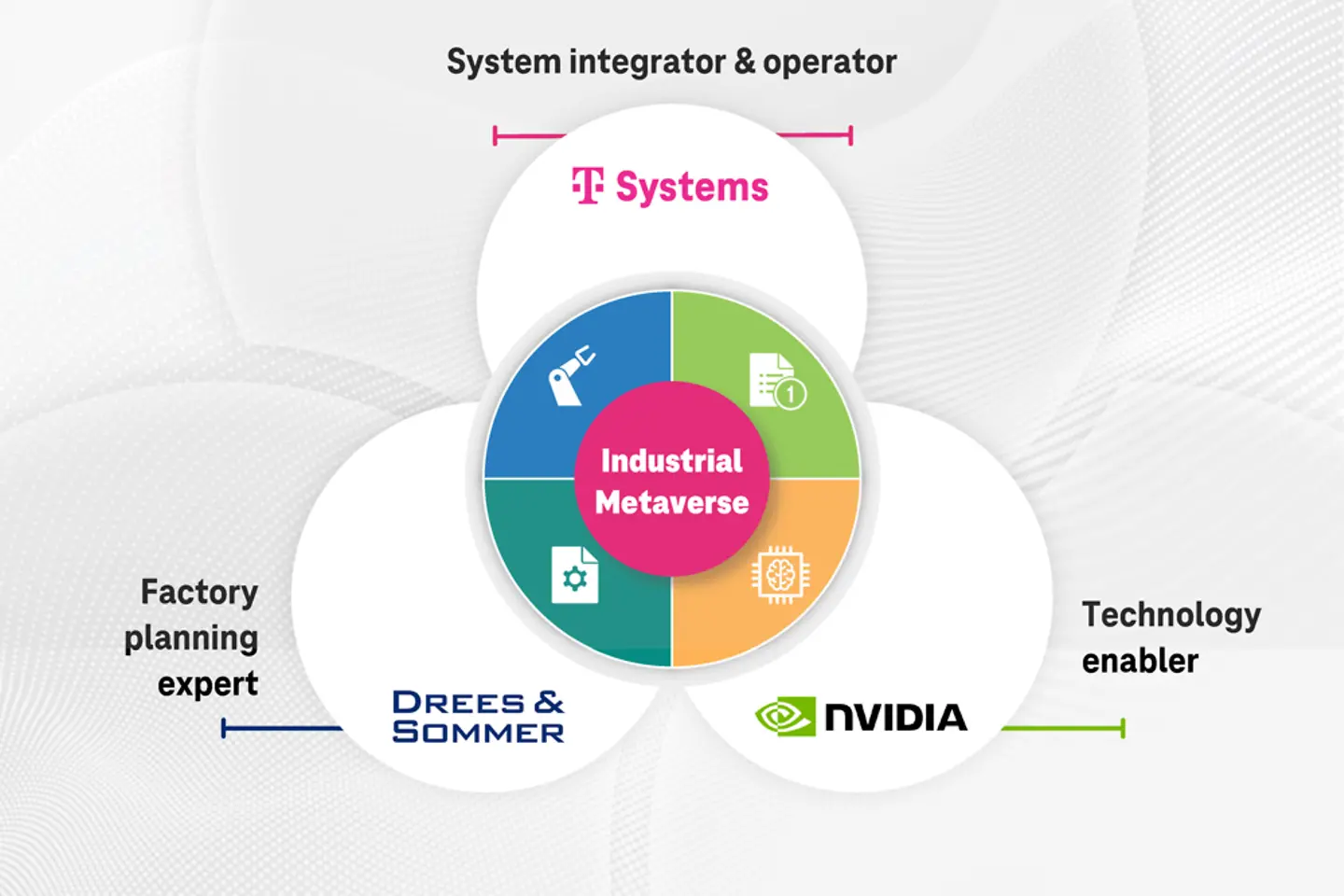

This collaboration harnesses the unique strengths of each partner. NVIDIA Omniverse provides an advanced platform for creating realistic virtual simulations, enabling the development and optimization of manufacturing processes. Drees & Sommer, with their extensive consulting expertise in factory and industrial projects, offer tailored strategies to effectively implement these digital solutions. T-Systems serves as the solution integrator, seamlessly embedding these advanced technologies into existing infrastructures, ensuring a cohesive blend of innovation and practicality.

The integration of digital twins has led to remarkable improvements in factory planning. By connecting various computer-aided design (CAD) tools and data through a unified Universal Scene Description (USD)-based data pipeline, manufacturers can create digital twins that enable cross-disciplinary and geographically dispersed teams to collaborate in real time. These advancements underscore the transformative potential of digital twins in industrial settings. Their real-world application demonstrates the practical benefits of integrating this technology in complex industrial environments.

Industrial companies of all sectors are going through a phase of change. The combination of technologies and know-how of our three firms is a real game changer. The huge number of possible applications offers manufacturing businesses a variety of solutions for factory and building design.

Christian Hort, Senior Vice President Automotive at T-Systems International GmbH

This collaboration offers increased flexibility, leading to efficiency and cost benefits in ongoing factory operations and during production area reorganizations. Additionally, the integration of multiple data sources into a unified digital twin improves data consistency, facilitating informed decision-making.

By optimizing energy consumption through precise planning and operations, the partnership contributes to a better CO₂ balance, aligning with global sustainability goals. This commitment to sustainability not only reduces operational costs but also enhances the environmental footprint of manufacturing processes, reflecting a responsible approach to industrial development.

The success of this partnership is evident in its collaborations with top car manufacturers. By consolidating multiple planning systems into a single platform, both internal teams and external partners can work together more efficiently. This results in improved planning quality and smoother commissioning processes.

Key insights from customer projects include:

As European manufacturers navigate a complex landscape marked by economic pressures and technological advancements, the collaboration among T-Systems, Drees & Sommer, and NVIDIA stands as a beacon of innovation. With its use of digital twin technology, this alliance not only addresses current industry challenges, but also paves the way for a more efficient, sustainable, and competitive future in manufacturing.