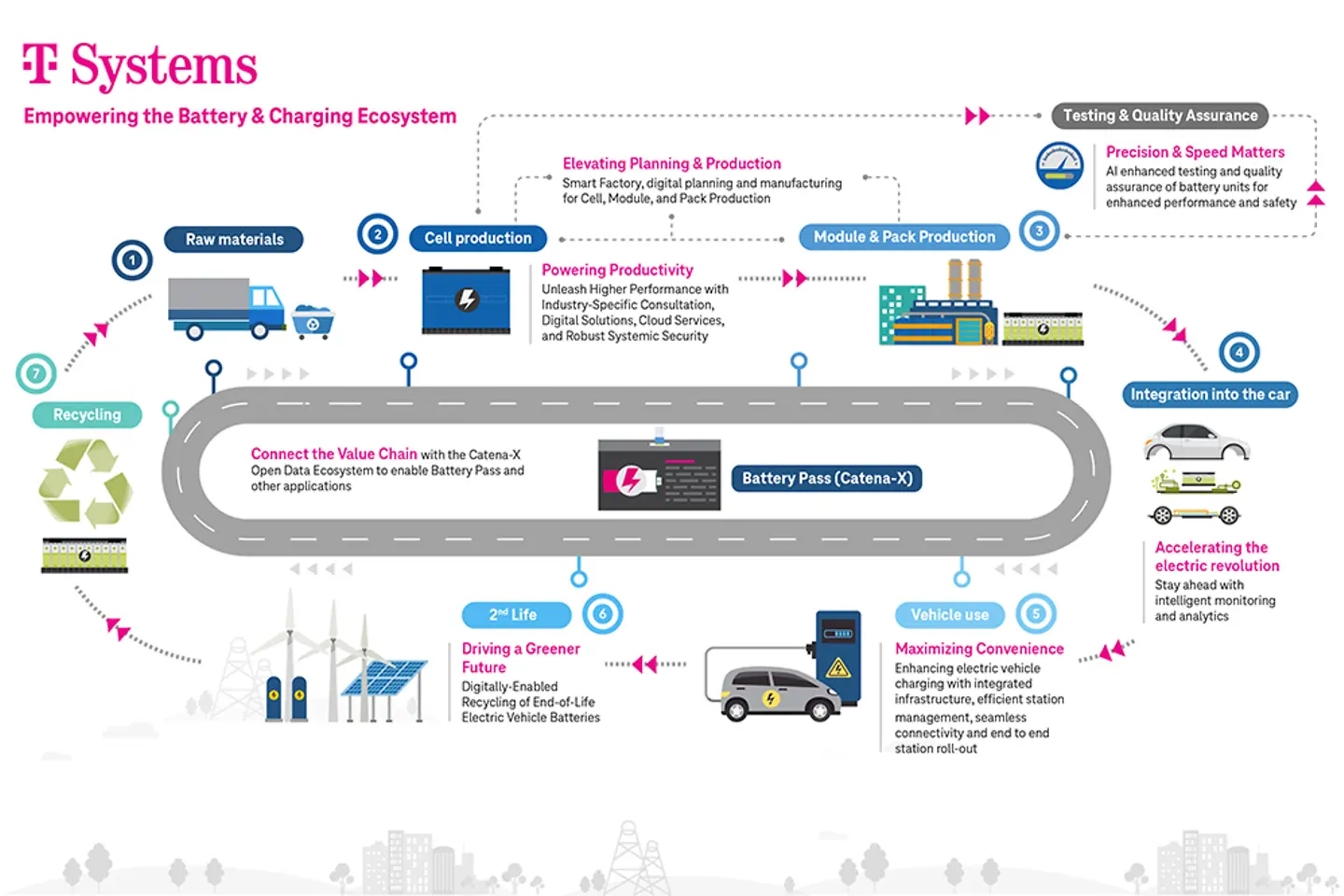

It is at the heart of the mobility transition and the most valuable part of an electric vehicle: the battery. So far, most manufacturers have been based in Asia. That is set to change: the EU and the German government are promoting the establishment of production capacity for battery development. The goal: greater speed in electromobility. After all, 15 million electric vehicles are expected to be on the road in Germany by 2030. Digitalisation can accelerate “made in Europe” battery production.

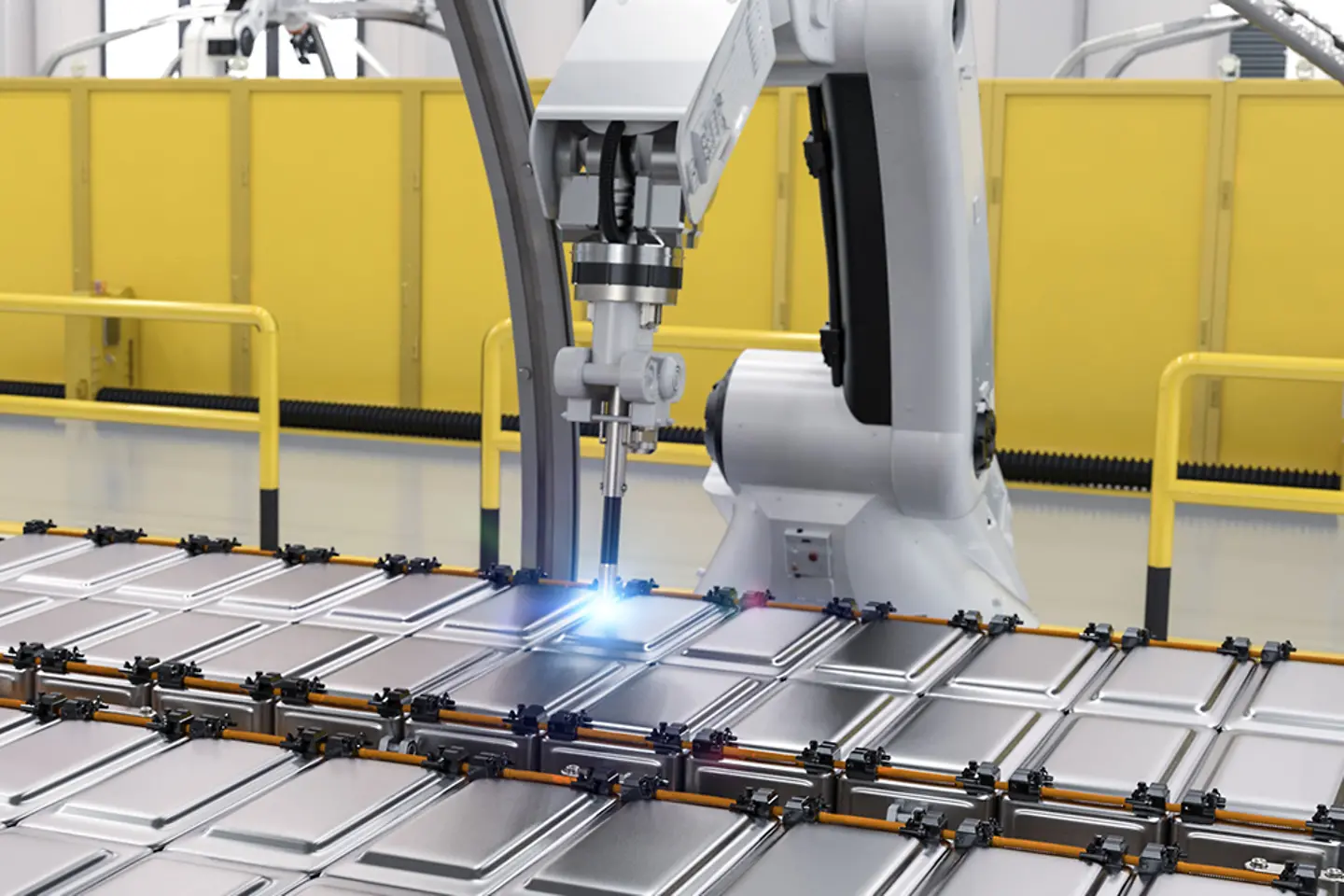

Production still has high reject rates. Manufacturers also need to think along the supply chain to a greater extent and to plan the efficient just-in-time provision of source components and raw materials. Digital technologies such as the IoT (Internet of Things) help to better coordinate supply chains and dovetail them with production planning. For more reliable and efficient quality control, manufacturers can combine cameras with established AI processes. For example, a solution from T-Systems helps to detect and rectify faults when checking weld seams.

In future, battery manufacturers will have to keep track of batteries throughout their entire service life – not least because the regulatory requirements for the industry introduced by the EU Battery Passport will place an even greater focus on sustainability from 2026. All processes relating to the materials, development, production, and operation of the battery cell must then be transparent: from the carbon footprint to the proportion of recycled materials. This transparency can be achieved with digital technologies.

Simulations in the industrial metaverse accelerate factory planning for Industry 4.0 and thus reduce project costs. Before the first walls and machines are built, battery manufacturers can optimise development, work, and production processes in the digital twin of their factory or train their AI in the industrial metaverse. With the support of T-Systems, a European OEM uses the industrial metaverse to clarify “what if” questions in real time. In the digital 3D model, it examines the effects of planned changes on production and thus avoids planning errors during operation.

Those looking to meet regulatory or industry-specific requirements must be able to record and provide their data. Catena-X has established itself as the standard for data exchange and can enable use cases such as the battery passport. T-Systems helps companies get started with Catena-X – for example with tools and technologies such as the PDM WebConnector. It functions like a central data hub and reduces the complexity of big data in the background. This makes it easier to exchange afterwards.

You can display all external content on the website at this point.

I agree that personal data may be transmitted to third-party platforms. Read more about this in our privacy policy.

Drive efficiency of EV cell and battery production with T-Systems

The EV production companies need the right partners who can help them utilize state-of-the-art digital technologies to plan, build, and optimize EV battery production facilities. Find out more about how companies can plan factories with digital twins, optimize processes with AI, and make battery production sustainable.

You can display all external content on the website at this point.

I agree that personal data may be transmitted to third-party platforms. Read more about this in our privacy policy.

Expert Talk: MES

What is an MES? How can it be used to digitally optimize production? What are the benefits of introducing an MES system?

You can display all external content on the website at this point.

I agree that personal data may be transmitted to third-party platforms. Read more about this in our privacy policy.

Expert Talk: Digitalization in industry

Frank Frauenhoffer (Amorph Systems Managing Director) and Wolfgang Weyand (T-Systems Sales Manager Digital) talk about digitalization in industry.

You can display all external content on the website at this point.

I agree that personal data may be transmitted to third-party platforms. Read more about this in our privacy policy.

Expert Talk: AI has reached the factory floor

Tobias Kasper (T-Systems Automotive & Manufacturing Industries) talks to Britta Hilt (IS Predict Managing Director) about artificial intelligence in the automotive industry.

You can display all external content on the website at this point.

I agree that personal data may be transmitted to third-party platforms. Read more about this in our privacy policy.

PLM Cloud & PDM WebConnector

In this episode, host Nathalie Dichtl (T-Systems Tribe Lead PLM Products) talks to Christian Engfer (Service Manager PLM Cloud) and Svilen Georgiev (Product Manager PDM WebConnector) about innovation and integration in automotive product management.

You can display all external content on the website at this point.

I agree that personal data may be transmitted to third-party platforms. Read more about this in our privacy policy.

Smart Engineering

Our experts, Tino Schlitt and Sascha Leidig, explain how networking and integrating data can simplify collaboration, increase the utilization and sharing of existing knowledge and expertise throughout your organization, and automate manual tasks.