Chemicals, pharmaceuticals, and electronics touch almost all aspects of our lives. They are drivers in making the biggest trends a reality. Today, these trends are more seismic and fast-acting than ever.

Process industries and electronics companies are re-tooling themselves to cut emissions. They are also trying to be closer to their customers, meet consumer-driven demands, and to communicate a wider sense of social and environmental purpose.

From a high-volume chemical shipment to a personal smartphone: anything that is manufactured in process and electronics industries comes with an emissions' cost. As consumption increases, manufacturers are racing against time to lower their environmental impact at every stage: from raw materials sourcing to product lifespan and circular economy solutions.

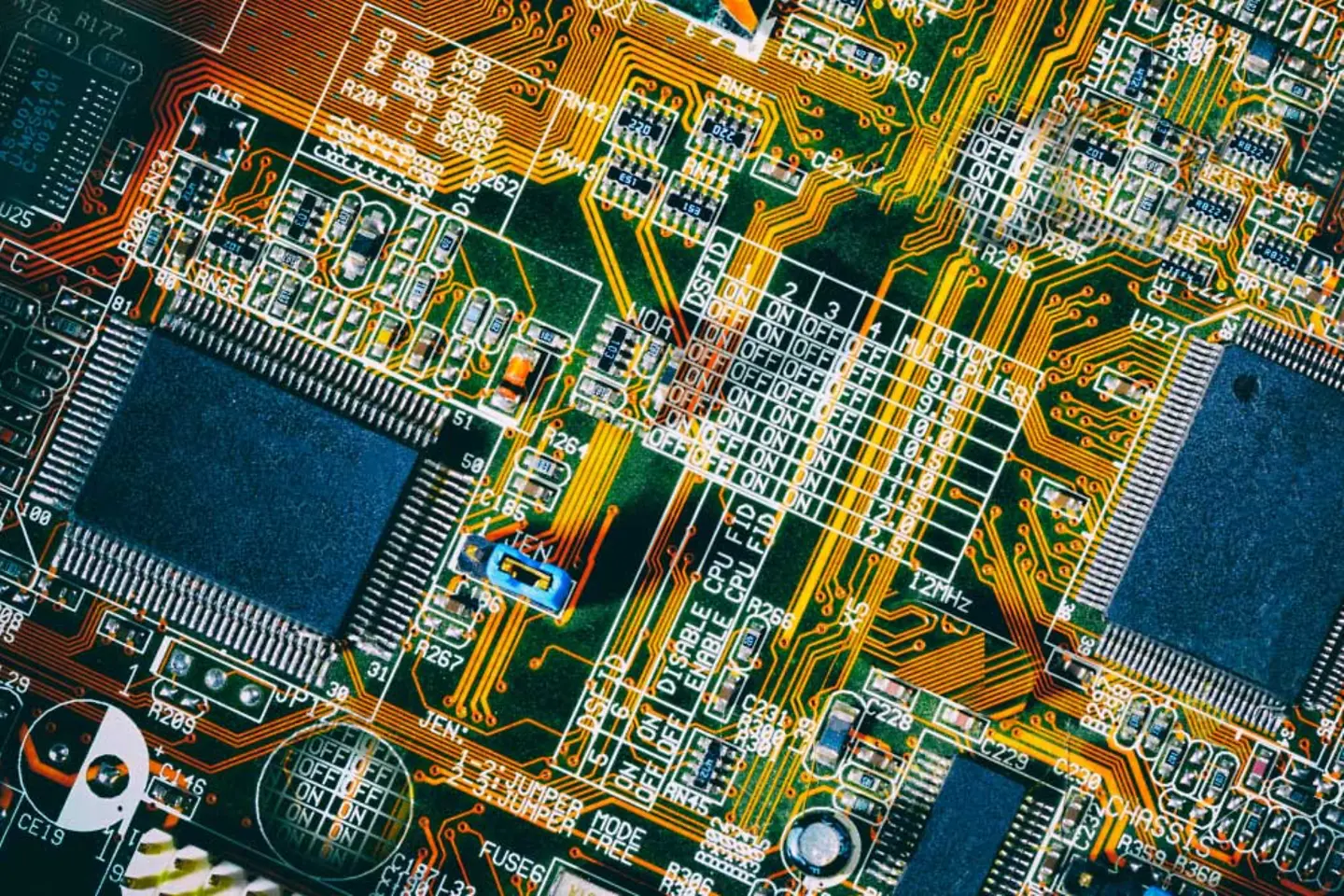

However, it is in manufacturing where the biggest gains can be achieved. 70-80% of the lifecycle carbon emissions of an electronic device are created during manufacturing.

This is leading to the rise of full energy management systems, which take a ‘big data’ approach to production efficiency. Through IoT manufacturing devices, the system can monitor energy consumption at a granular level, preventing energy spikes and finding ways to reduce expenditure without jeopardizing mission-critical processes.

This end-to-end system can offer a new level of insight into where emissions are really incurred. They are the next generation of climate-smart technology helping manufacturers comply with regulations, cut costs, and meet the demands of sustainability-focused customers.

Merely optimizing production is not enough to cut emissions. Entire supply chains need to be optimized. After the disruption caused by the pandemic, companies over the world are redesigning supply networks to add flexibility, redundancy, and a greater degree of localization.

With significant rise in raw materials requirements, chemicals and electronics are affected the most. Industry 4.0 solutions can play a key role here: AI to provide insight on optimal timings and reduce downtime, and blockchain to provide transactional transparency. As uptake accelerates, change becomes default rather than an option.

While industry leaders struggle with global challenges, they are also facing increased competition, driven by fast-proliferating start-ups and developing economies taking a greater market share.

Hence, they must adopt new offerings inspired by consumer industries. In these new business models, pricing is set dynamically by AI, the entire offer-to-cash loop is shortened, and customers buy integrated, instantly available services rather than simply products.

IT needs to support this new model, not get in the way. When software and processes function together seamlessly, it will be fully realized.