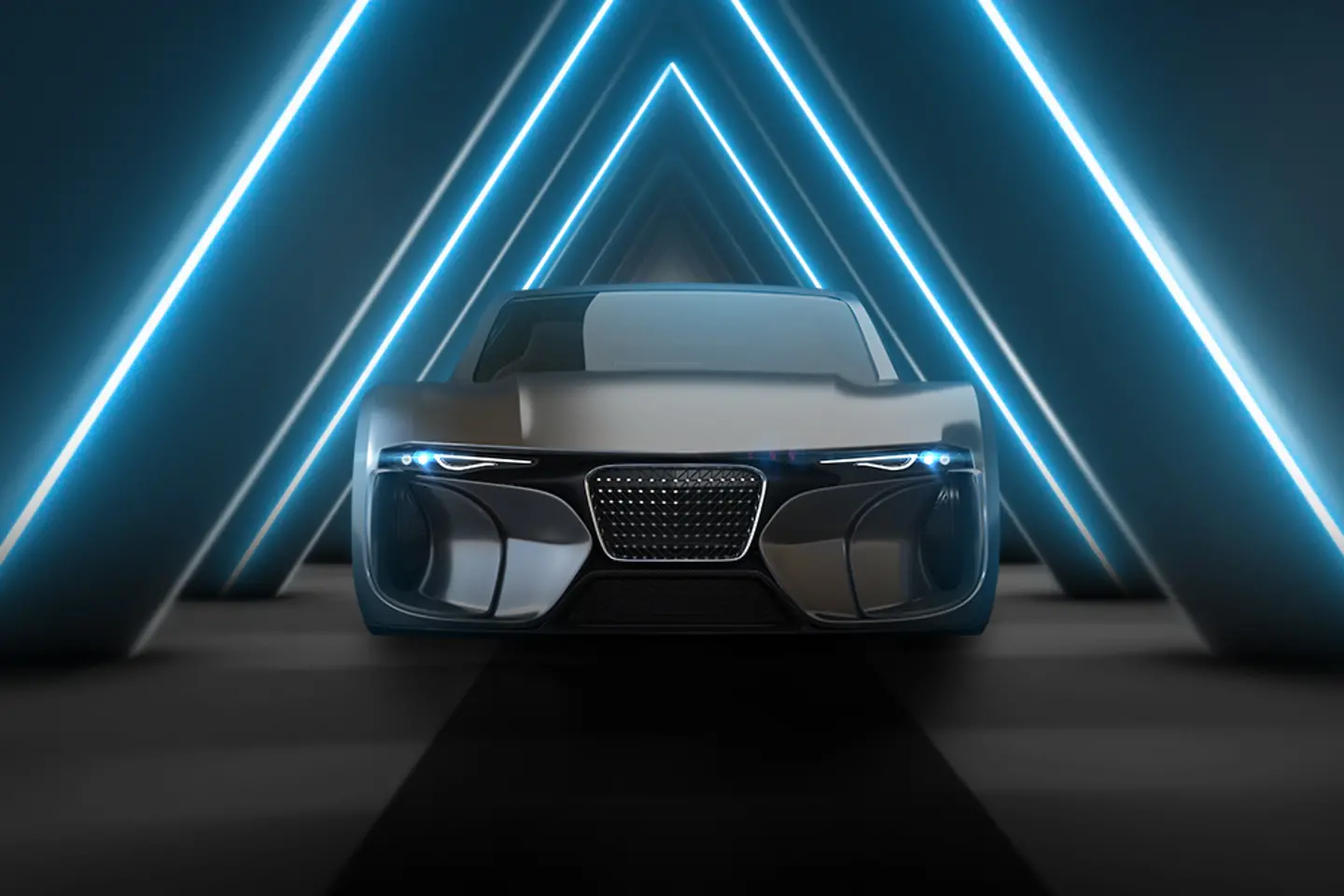

The automotive sector is undergoing rapid transformation. From electric vehicles to autonomy, from classic to new challenger OEMs, innovations are reshaping how we engineer, manufacture, and interact with automobiles, promising a future of sustainability, safety, comfort, and connectivity. Find out how T-Systems empowers the automotive value chain as a trusted partner for digital transformation.