The journey to the digital future is constantly evolving. To remain competitive, companies must accelerate their digital transformation. New business models, the creation of unique customer experiences and the use of precise data analyses help in this process. This is where we can be your trusted partner on the path to seamless digital transformation and evolution.

More emotionality, a personalized approach, or the optimal linking of individual digital touchpoints: Customer experience has become one of the most important differentiators today. Well-informed and satisfied customers remain loyal to your company in the long term. Improving the customer experience is therefore no longer a nice-to-have, but a necessary measure to sustainably increase the company's image and sales with satisfied customers. We help you to develop and implement the appropriate, overarching strategy for the customer experience.

More convenience, more personalization and more speed: Can your current business model meet the increasing demands of customers? In order to retain customers in the long term, it is important to respond quickly and effectively to their individual needs. According to a study by the consulting firm Detecon, the companies which will be successful in this regard will be those which provide data-based products and services, enable digital interfaces, and digitalize their business processes.

Intelligent data analytics help companies better understand and respond to customer needs. They also help management and business departments to make the right decisions. To do this, data must be made transparent across the company and made available to all teams – as far as compliance and security aspects allow. If data analysis is an integral part of your strategy, you will gain a major competitive advantage. You can make more accurate forecasts, act more effectively, and make your company more resilient.

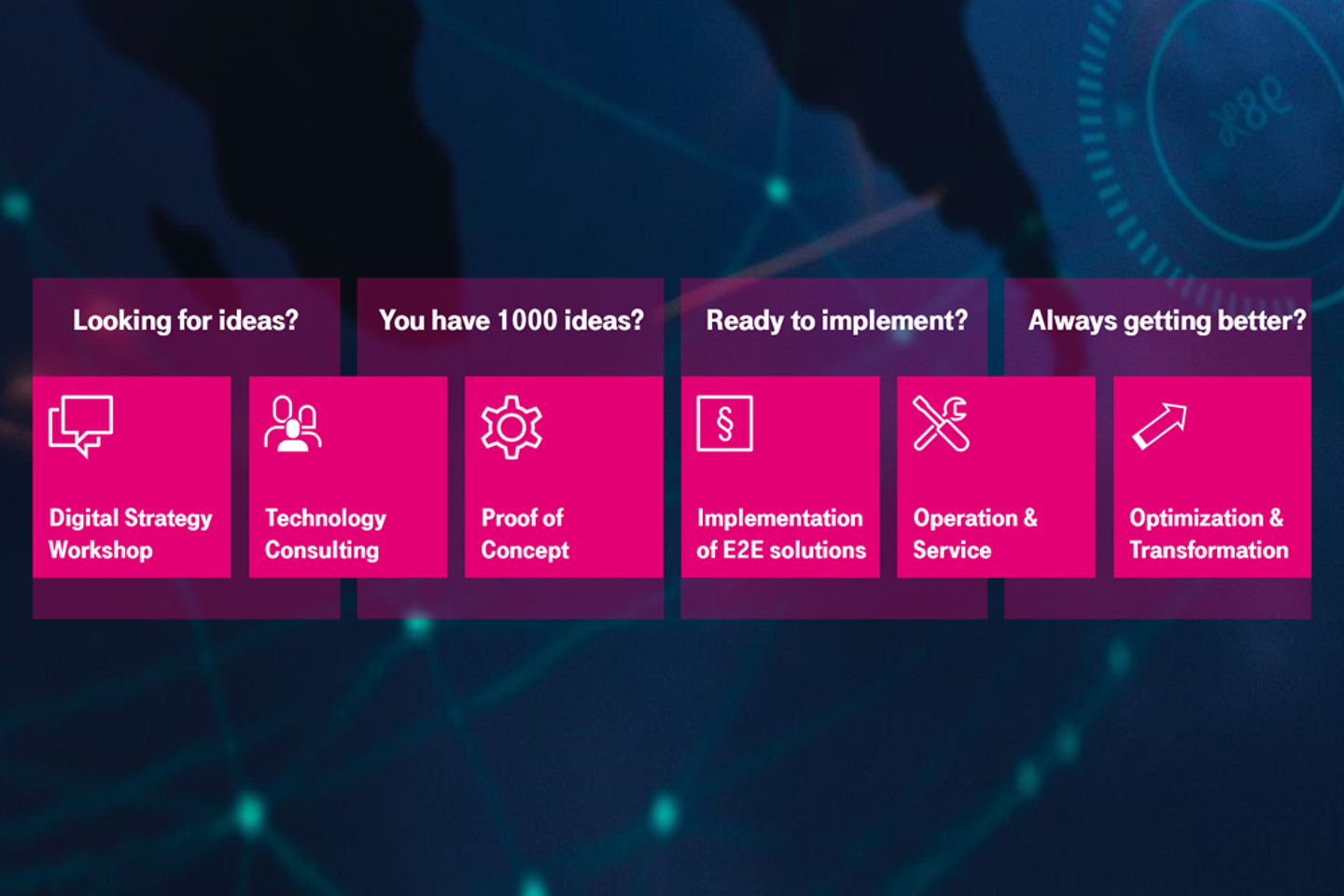

Making a company or business unit “digital” requires strategic planning, reliable technologies, and a competent partner. We can help you to integrate many different things optimally. No matter where you are on your journey.