In the era of digitalization, the independence and intelligence of objects is increasing. This applies in particular to our value chains, which have become flexible and dynamic as a consequence. The digitalization of our processes and products leads to an exponential growth in data and their processing algorithms.

On an assembly line, for example, thousands of sensors are used, a forklift can independently calculate from its use when it will need replacement parts and which ones, a warehouse software program knows its inventory and independently orders supplies, chips are even built into drilling machines nowadays.

Machines and products manage their own condition and jobs, autonomously communicating with other objects. Artificial intelligence recognizes decision and behavior patterns, and supports people during their routine activities.

So, to be successful in digital competition with other companies, we need to be able to:

For this all to work, everything must run securely and reliably.

The campus edge toolkit from Telekom/T-Systems can help you to master these challenges.

Let us consider a campus as a closed-off geographical region: this could be a production or logistics site or even a retail store.

For this campus, we will set up an internal connectivity network, which is geared toward the needs of the campus operation. Here, 5G offers us new options with regard to data volumes and transmission speed. Because, with the demands of digitalization, established technologies are being pushed to their limits. With 5G, Deutsche Telekom can offer you an exclusive portion of its network with guaranteed service features. However, it is also conceivable that, as before, 4G, industrial WiFI, or cable connectivity will come into play.

The edge is a supercomputer, the heart and brain of the digitalization of a campus, if you will. It is with reference to the edge that a local cloud ecosystem is configured. This is linked to a cloud, with which it shares functions and data and to this end is directly linked with the communication network. T-Systems can certainly integrate conventional cloud ecosystems, but with the EdgeAir, it has developed a special solution, which is high-performing and handles your data securely in accordance with the European General Data Protection Regulation (GDPR).

This lays the foundation for using and developing applications which make your campus even more efficient than it is today.

Image 1: AGV with 5G connection and navigation via edge computing.

Before we take a look at a few usage scenarios, let us think about the five relevant advantages of campus edge solutions.

(1) Ultra low latency – Systems can be managed in real time. Imagine a scenario in which the gestures of a person are transmitted to a robot in milliseconds.

(2) Off-device computing – Thanks to increased processing speeds and data bandwidth, the edge can take over tasks which were previously processed in the device. Route planning for autonomous guided vehicles (AGVs) can, for example, take place centrally on the edge.

(3) Multi device orchestration – Transferring the control of multiple devices to the edge allows them to be controlled independently from one another. Communication between the AGVs for the exchange of information pertaining to obstacles can also be displayed. All this regardless of the respective AGV manufacturer. You now have flexibility even in your choice of AGVs, since central functions and AGV networking take place on the edge.

(4) Security – For an individual campus, a closed communication network is developed, so that it is better protected from virtual attacks.

(5) Data condensation – This is the preprocessing of data on the edge, in order to avoid the transmission of massive data volumes, such as status information from machines, AGVs, or video data for object recognition over public communication networks.

In summary, we can say that with campus edge, we can build new data processing hubs, which form an interface between your data centers and a cloud operation, to distribute data flows and processing in such a way as to maximize efficiency.

These five advantages can be applied to many use cases, be that in production, logistics, or on other campus scenarios. Let's take a look at an example,

imagine a production campus:

Autonomous guided vehicles are unnamed delivery vehicles which transports goods to the production area. Previously these robots moved on loops and therefore could only travel along predefined paths. Thanks to campus edge and wireless connectivity, we can move them anywhere and link new production sites and storage areas, optimally steer an entire swarm, and deal with unforeseen situations, such as a blocked path, for example.

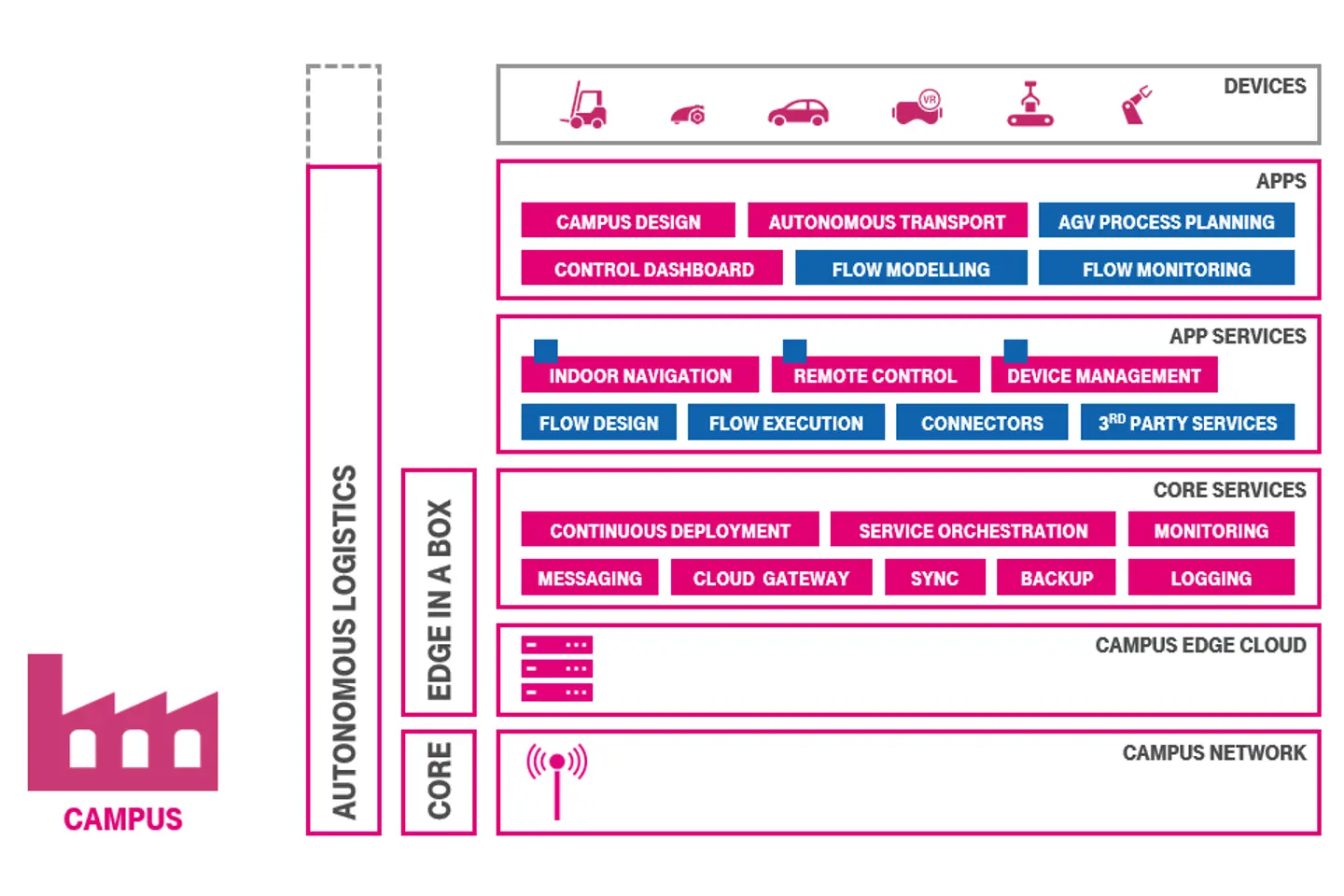

Image 2: E2E integration for the autonomous logistics solution.

The process of optimizing, integrating, automating, and managing all physical logistical processes from delivery, production, and distribution plays an important role in flexibly linking production processes. AGVs do not meet the requirements for these intralogistical challenges. Autonomous navigation is essential for making flexible adjustments and optimized material transport (e.g. avoiding obstacles through dynamic pathway planning). Consequently, real-time processing is necessary to steer the AGV radio unit (low latency).

The product “Autonomous Logistics” offers software solutions in the context of 5G campus networks with an edge infrastructure. Within this framework, services are created for the purposes of automating transport across the customer's premises.

Customer requirements are implemented both for the digitalization of analog processes and for improving the flexibility of production processes. The transport of replacement parts, goods etc. can take place both inside buildings and outside. The approach consists of setting up the new system and integrating it into existing systems with minimal effort and training of employees.

The customer benefits from this approach:

The developed services encompass the integration and connection of various AGVs (vendor agnostic), machines and sensors, which are provided by partner companies within the framework of joint customer approaches. To enable transport from A to B, the FTF must know where it is, which is enabled by a localization component. To this end, various sensor information from the FTF is used and displayed alongside information about its environment (walls, people, etc.). When multiple vehicles are in use alongside the transport orders, fleet structures can also be used to enable optimization.

Figure 3: Orchestration of solutions with the campus edge toolkit.

We provide you with our campus edge toolkit and can support you from consultation through implementation and managed services – end to end and from a single source.

Irrespective of your goals and implementation plans, we can offer you the necessary connectivity, computing power, and the most advantageous development ecosystem.

In addition, you can use our predefined services, such as our Positioning Service, with which you can consistently and precisely locate movable objects; an IoT management system for controlling numerous sensors and actuators; or an integration engine to smoothly dovetail your processes together.

Moreover, we offer you finished products, such as the central control system for AGVs, a solution for device maintenance incorporating artificial intelligence and virtual/augmented reality, or solutions concerning optical recognition. All of this can enable you to reach new levels of quality and efficiency for your products and processes in just a short time.