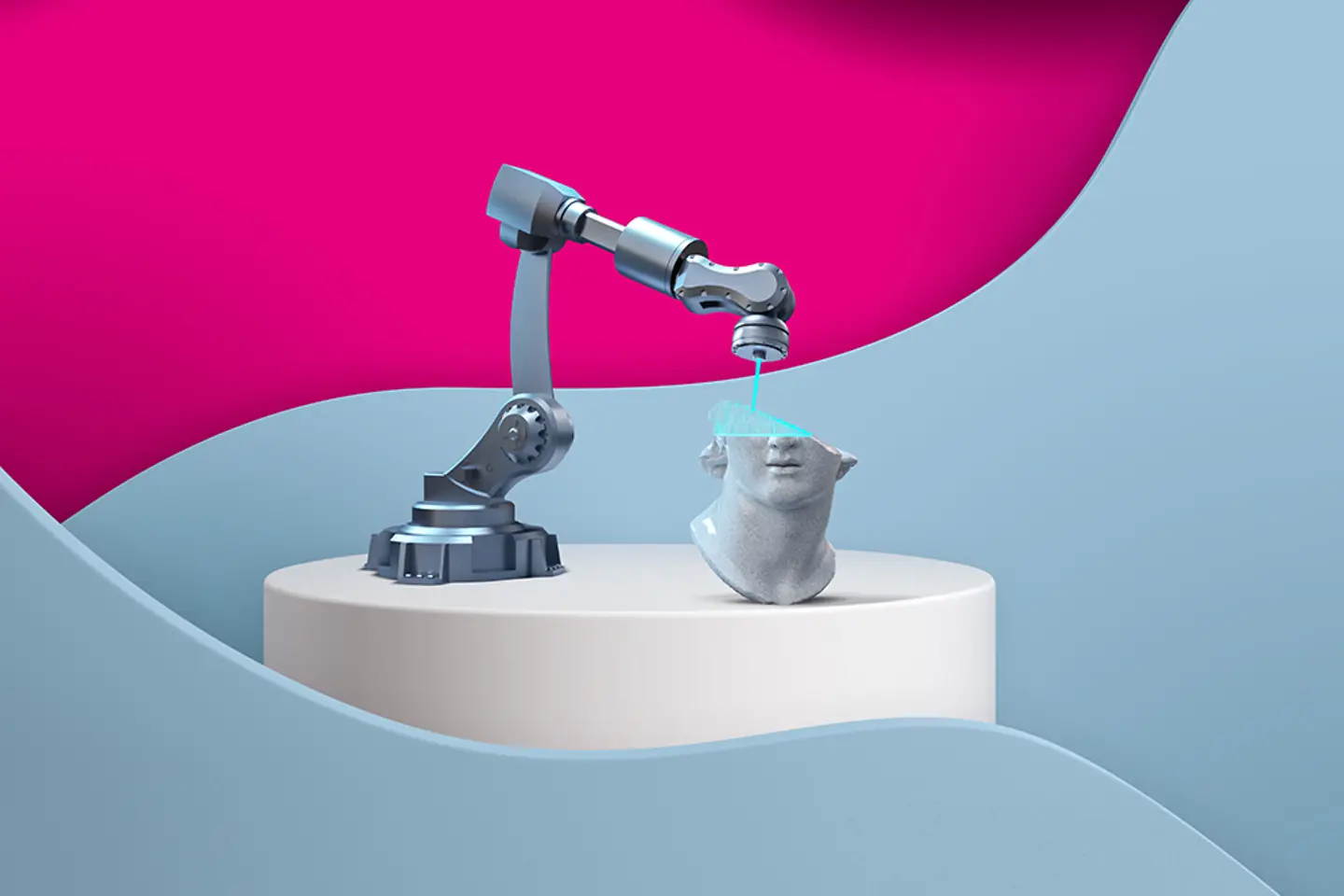

The manufacturing sector is undergoing digital transformation driven by intensifying global competition, evolving consumer habits, supply chain disruptions and new sustainability regulations. Manufacturers are embracing AI and Industry 4.0 to stay competitive. T-Systems’ solutions enables manufacturing companies improve production performance across the entire value chain.